Why is it worth using spray Polyurethane foam insulation?

Spray polyurethane foam insulation, no matter if it is applied on foundation or/and elevation of a building, has several unique features that traditional insulating materials, like mineral wool or Styrofoam, don’t have.

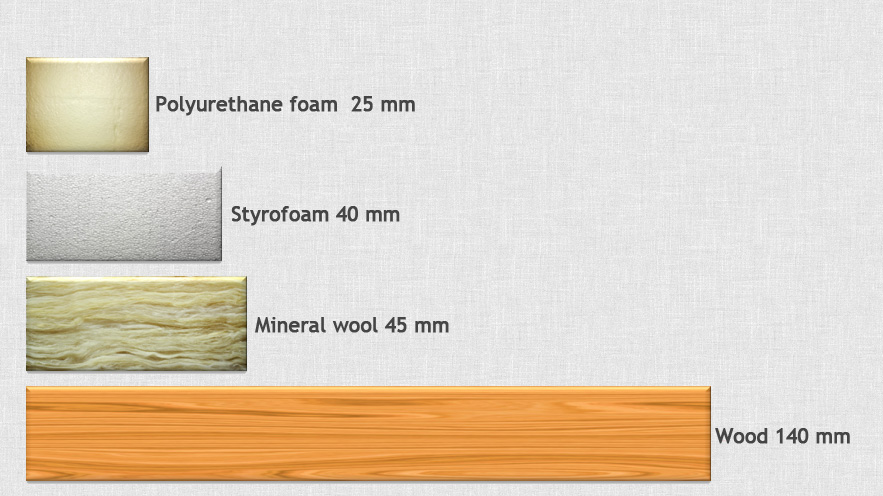

Key advantage of Spray Polyurethane foam insulation is low rate of heat transfer coefficient. This characteristic causes that a layer of a Polyurethane foam is thinner than a layer of mineral wool or Styrofoam although heat transfer coefficient is the same.

Exemplary thickness of spray polyurethane foam insulation layer in comparison to mineral wool, Styrofoam and wood insulation, with the same heat transfer coefficient rate.

Because of its adhesion polyurethane foam can be applied on any surface, and as it solidifies quickly, the foam doesn’t get off. When it can be exposed to UV, it is covered with a special paint. This also gives additional hydro insulation and enhances aesthetic value.

It is a versatile insulating material.

Key features of spray polyurethane foam insulation in comparison to mineral wool and Styrofoam insulation.

|

Polyurethane foam |

Mineral wool |

Styrofoam |

|---|---|---|

|

Non-inflammatory Spray polyurethane foam insulation eliminates a risk of lack of a sufficient tightness Works like an impregnate. It protects wood from mould and metals from corrosion. It adjusts itself to all surfaces and shapes Has very good thermal insulating properties. Creates hydro insulating layer. Works as a barrier against moist, prevents moulds and fungi. |

Non-inflammatory Relatively high thermal and acoustic insulation Often used for thermal insulation of attics because it can be fitted to rafter’s shape Absorbs air moist which negatively influences its insulating properties Often moves thus creating leaks |

Good thermal insulating properties Bad acoustic insulation Because of its brittleness and rigidness it’s difficult to adjust it to a particular shape and fill hard to reach places Low resistance to high temperatures |